Tiếng Việt

Tiếng Việt

Commodity: Bimetal Inlaid self-lubricating bearing

Origin: China, Germany, Japan

Price: Negotiate

Specification: Order

Warranty: 02 years

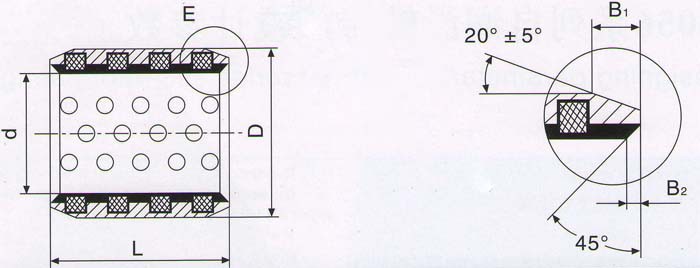

Bimetal inlaid self-lubricating bearings is made from medium or low carbon steel and the friction surface layer is the copper alloy with sufficient thickness and the two parts are firmly intergrated. On the friction surface layer, there are a certain number of blind holes (when the inner diameter is more than 200mm) or through holes (when the inner diameter is equal or less than 200mm) in which solid lubricant is inlaid, in the meantime, the surface of friction layer of the bearing is smeared with solid lubricating film that is helpful to the running - in procedure.

Advvantage:

- Saving material, high loading capacity, lower cost

- Low friction coefficient.

- High abrasive resistance

- Various motion status of low speed and heavy load and the lubricating oil film can not be maintained.

- Owing to the restriction and limitation of the working enviroment or mechanical structure, it is difficult to provide oil for lubrication.

- Shock load is easily emerging during the work

- Working under the conditions of high temperature or low temperature or the ambient temperature changes in a wide range.

Mechanical material property

| Allowable static load | N / mm ² | 280 |

| Allowable dynamic load | N / mm ² | 160 |

| PV limit factor P=75 MPa | N / mm ² xm / s | 1,6 |

| Friction coefficient | μ | 0,08 to 0,12 |

| Ranges of operating temperature | ° C | -80 to +250 |

| Housing bore diameter | H7 |

| Bearing outer diameter | s6 |

| Bearing bore diameter | E8 before installation, H10 after installation |

| Shaft diameter | d8 |

| Hardness of shaft | hardness> 180 HB |

| Roughness | Ra 0,2 - 0,8 micromet |

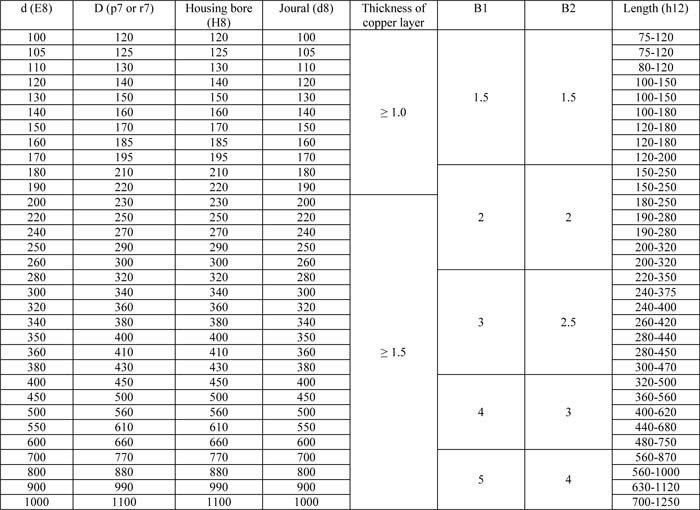

Dimension